Gasanalyse

Multi-Flue UV-DOAS Analysator

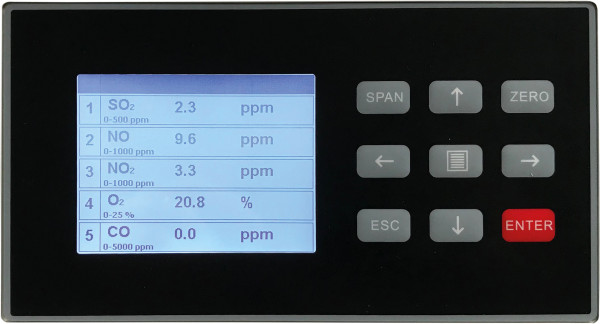

Multi Gas analyser based on UV DOAS and chemometrics algorithms (PLS), able to perform the measure of SO2, NO, NO2, NH3, Cl2, H2S and others. In addition, the instrument can integrated a reliable electrochemical cell for O2, and a Laser TDLAS bench for measuring CO or CH4.

Multi Gas analyser based on UV DOAS and chemometrics algorithms (PLS), able to perform the measure of SO2, NO, NO2, NH3, Cl2, H2S and others. In addition, the instrument can integrated a reliable electrochemical cell for O2, and a Laser TDLAS bench for measuring CO or CH4.

It can be widely used in environmental online monitoring, industrial process control, safety monitoring, etc.

Measureable Gas

- Nitric Oxide [NO]

- Oxygen [O2]

- Chlorine [Cl2]

- Nitrogen Dioxide [NO2]

- Carbon Monoxide [CO]

- Hydrogen Sulphide [H2S]

- Sulfur Dioxide [SO2]

- Ammonia [NH3]

- Methane [CH4]

Main Features

High Measurement Accuracy

- The minimum detection limit of SO2, NO, NO2 can be 1mg/m3 (15 m optical path)

- Ultraviolet has no moisture absorption: undisturbed by moisture and dust.

- No cross interference between the gas being measured

- NO and NO2 can be measured at the same time, dispense with converter.

- Low detection limit.

High Reliability

- DOAS + PLS technology, small amount of zero drift and span drift

- Modular design

- Available version with external UV bench for use with toxic or corrosive gases.

- No optical moving parts and no vibration influence.

- Strong gas cell, low cost.

- Spectrum automatic adjustment technology, long free maintenance cycle

- Light source adopts the pulse source; the service life is 10 years

European Compliance

- Low Voltage Directive 2014/35/EU

- EMC Directive 2014/30/EU

|

Model |

Multi-Flue-S (standard) |

Multi-Flue-LE (Low Emission) |

Multi-Flue-ULE (UltraLow Emission) |

||||

|

Measuring Principle |

UV DOAS + PLS (all the gas); Zirconia (O2); Electrochemical (O2 & CO); Laser (CO) |

||||||

|

Typical Measured Gas |

Min. |

Max. |

Min. |

Max. |

Min. |

Max. |

|

|

Detection Range |

SO2 |

0-300 ppm |

0-3000 ppm |

0-100 ppm |

0-300 ppm |

0-50 ppm |

0-100 ppm |

|

NO |

0-300 ppm |

0-3000 ppm |

0-100 ppm |

0-300 ppm |

0-50 ppm |

0-100 ppm |

|

|

NO2 |

0-1500 ppm |

0-15000 ppm |

0-200 ppm |

0-500 ppm |

0-100 ppm |

0-200 ppm |

|

|

O2 |

0-5% |

0-25% |

0-5% |

0-25% |

0-5% |

0-25% |

|

|

Others |

For CO, NH3, H2S, Cl2 and O2 range and feasibility must be evaluated accordingly to the stream gas |

||||||

|

Linearity |

≤ ±1.5% FS |

||||||

|

Repeatability |

≤ ±0.5% FS |

||||||

|

Zero & Span Drift |

≤ ±2% FS |

||||||

|

Response time (T90) |

< 10 sec. |

< 30 sec. |

< 30 sec. |

||||

|

Working Temperature |

-10°C….+40°C |

||||||

|

Warmup Time |

No pre-heating |

Approx. 10 min. |

|||||

|

Sample Gas Interface |

Ø6 Bi-lok |

||||||

|

Sample Gas Flow |

0.5…2 l/min., Fluctuation < 25% |

||||||

|

Sample Gas Pressure |

The current environmental pressure ±0.1 Bar |

||||||

|

Sample Temperature |

0°C….+50°C |

||||||

|

Sample Gas Humidity |

Non condensation (under sample temperature) |

||||||

|

4-20 mA Input Interface |

3 x configurable, max. load 100 Ω |

||||||

|

4-20 mA Output Interface |

5 x configurable, max. load < 800 Ω |

||||||

|

Switch Input Interface |

6 x configurable |

||||||

|

Relay Output Interface |

14 x configurable, 30 VDC, 2A |

||||||

|

Communication Interface |

1 x RS232, 1x RS 485 (ModBus) |

||||||

|

Installation |

Rack 19" |

||||||

|

Supply |

100...240 VAC |

||||||

|

Power |

~ 100W |

~ 200W |

|||||

|

Outline Dimensions |

132(H) x 483(W) x 378(D) mm |

177(H) x 483(W) x 412(D) mm |

177(H) x 483(W) x 412(D) mm |

||||

|

Weight |

~ 10 Kg. |

~ 12 Kg. |

|||||

Application

- DeSOx process monitoring

- DeNOx process monitoring

- Flue gas continuous emission monitoring

- Chlor-alkali plant PVC process

- Titanium white production process

- Sulfur recovery process

- Natural gas purification process

- Methyl iodide analysis for the coal chemical industry.

- On-line air monitoring

- Power plants

- Industrial furnaces

- Incinerators

Sampling System

The Multi-Flue needs an external sampling system able to deliver an almost clean sample gas to the analyser at the proper temperature, pressure and flow rate.

ADEV has a wide experience in process and can provide the Multi-Flue analyser combined with a sample and condition system designed for the specific application requirements. Contact ADEV for details

Measuring Principle

Multi-Flue gas analyzer applies UV DOAS technology. The optical technology platform consists of light sources, gas chamber, optical and spectroscopic (including diaphragm, holographic grating, linear array detector) and other optical components.

Ultraviolet light is sent by the light source through the optical window into gas chamber; absorbed by the sample gas through the gas chamber. The light carrying sample absorption information gathers through lens coupled into fiber and then transmits through the optical fiber into spectrometer. After light splitting and photo-voltaic, conversion, absorption spectrum is obtained and analyzed to calculate the concentration of the related components in gas.