Gasanalyse

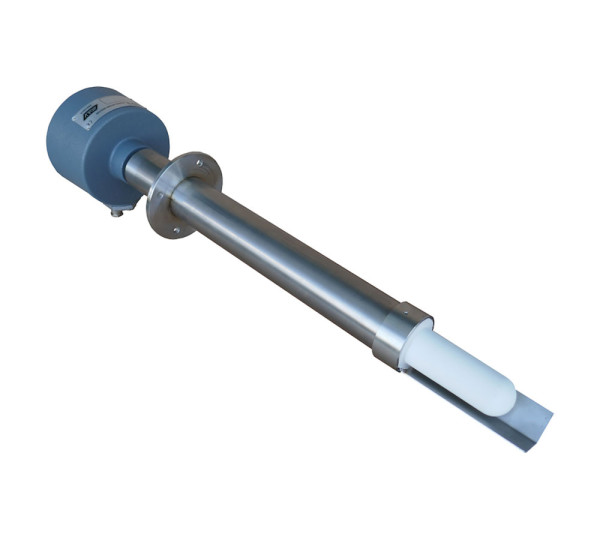

7873 Zirkoniumoxid Rauchgasanalysator

Self-heated probe, designed to measure Oxygen in flue gas (up to 700°C). Designed to measure Oxygen in flue gas for combustion efficiency and fuel saving in big boilers and power plants fed by Natural Gas, light and heavy oils, LPG, Biomass and Coal.

Self-heated probe, designed to measure Oxygen in flue gas (up to 700°C). Designed to measure Oxygen in flue gas for combustion efficiency and fuel Self-heated probe, designed to measure Oxygen in flue gas (up to 700°C). Designed to measure Oxygen in flue gas for combustion efficiency and fuel saving in big boilers and power plants fed by Natural Gas, light and heavy oils, LPG, Biomass and Coal.

Available as a transmitter with 4-20 mA output from the probe head or combined with a control unit / display.saving in big boilers and power plants fed by Natural Gas, light and heavy oils, LPG, Biomass and Coal.

Measureable Gas

Oxygen [O2]

Main Features

Extreme Roughness

Rugged materials contacting the process gas

- Usable in flue gas up to 700°C, either continuously or cyclically

- Do not suffer damage or deformation

- Installation and protection tube makes the probe suitable for high dust flue gas, avoiding abrasion and sticking of dirty material.

- Different types of filter mesh and deflector plate to put against gas flow to limit the dust impact on the sensor:

Ceramic fiber mesh: Suitable for non-sticking dust and moderate flow rate applications.

Ceramic mesh: Suitable for high dust, sticking particulate and high flow rate that may generate abrasive effect.

Metallic Stainless Steel sintered filter: suitable for highly abrasive dusts and high flow rates inside the stack

No Critical Parts

Potentially critical solutions have been avoided such as internal welds, critical couplings and separation of the reference atmospheres from the measurement atmospheres:

Easy to Use and Service

Direct insertion into the smokestack or duct

Possibility to check the calibration without removing the probe from process

All components parts easily accessible and field serviceable.

Sensor assembly replaceable without removal of the probe from its mounting.

European Compliance

Low Voltage Directive 2014/35/EU

EMC Directive 2014/30/EU

|

Probe Specification |

|

|

Accuracy |

0.1% O2 below 5% or 2% of reading above 5% |

|

Zero Drift |

± 2% of reading in 3 months |

|

Repeatability |

± 1% of reading (short term) |

|

Response Time |

less than 5 sec. at T95 (with flow rate 2 l/min.) |

|

Probe Head Protection |

IP65 |

|

Weight |

~ 1.5 ÷ 2.5 Kg. Depending on probe length (excluded installation tube) |

|

Wiring Connections |

N°1 cable gland for cable max. 10 mm and inner terminal strip |

|

Pneumatic Connections |

Reference and calibration air inlet: 1/8” NPT-F |

|

Gas |

Oxygen (O2) |

|

Measuring Principle |

Zirconium Oxide (Zirconia) |

|

Sensor Output |

E.M.F. function of Oxygen concentration |

|

TC Output |

E.M.F. function of the temperature |

|

Type of Thermocouples |

Standard type B (pt 6 Rh-Pt 30 Rh). In alternative type S |

|

Humidity |

0….90% non condensing |

|

Temperature Range |

600°C to 1250°C |

|

Head Temperature |

Max. 130°C |

|

Reference Air |

Dry, clean and oil-free air. Flow rate: 100…200 cc/min. |

|

ADV222 Control Unit Specification |

|

|

Analog Inputs |

2 x isolated (1 for O2 and 1 for Temperature) |

|

Analog Outputs |

2 x 4-20 mA isolated (1 for O2 and 1 for Temperature) |

|

Output Resolution |

better than 1x10.000 of FS |

|

Relays |

N°2 relays SPDT, 230 VAC, nominal 2A (max 4A) * |

|

Power Supply |

8...28 VDC ; 9...24 VAC |

|

Ranges |

0-25% O2 ; 0-1200°C ** |

|

Operative Temperature |

-20°C…+70°C |

|

Humidity |

0….90% non condensing |

|

Led |

Power supply (blue) - Cumulative inputs overload (red) - TX/RX (yellow/amber) |

|

Serial Interface |

RS485 2-wire (Protocol ModBus-RTU) |

|

Line Impedance |

120 ohm |

|

Termination Type |

External |

|

Max Speed |

57600bps |

|

Max No. of Nodes |

32 |

* Threshold to be selected at order (factory set) or settable in field by PC with ADEV Easy Configurator

** Default ranges factory set. Modifiable on request at order on customer specification or by PC with ADEV Easy Configurator

|

Supplementary ADbox Specification |

|

|

Protection |

IP55 |

|

Weight / Dimensions |

8 Kg. / 400 x 300 x 150 mm |

|

Power Supply |

100...240 VAC, 2A, 50/60 Hz. |

|

Display |

LCD 2.42” OLED . Resolution0.01% |

|

Cable Entrance (bottom) |

N°4 cable glands PG 13 / 9 / 7 |

|

Supplementary ADcase Specification |

|

|

Protection |

IP55 |

|

Weight / Dimensions |

10 Kg. / 400 x 300 x 150 mm |

|

Power Supply |

100...240 VAC, 2A, 50/60 Hz. |

|

Display |

LCD 2.42” OLED . Resolution0.01% |

|

Cable Entrance (bottom) |

N°4 cable glands PG 13 / 9 / 7 |

|

Pneumatic Connections |

Reference and calibration air inlets: 1/8” NPT-F |

|

Configurations |

1: Pressure reducer & manual valve 2: Pressure reducer & electro valve 3: Pump & manual valve 4: Pump & electro valve |

Applications

Industrial boilers using any type of fuel: Natural gas, LPG, light oils, heavy oils, diesel, coal, biomass

- Utility Boilers

- Recovery Boilers

- Low Temperature Incinerators

- Power Plants

- Cement Kilns

- Industrial Furnaces

Other combustion processes where flue gas is within temperatures limits (within 700°C)

Measuring Principle

The measuring principle on which the analysis is based is linked to the use of Zirconium oxide which, at high temperatures, can behave like a solid state electrolyte, developing an electromotive force on two electrodes placed in contact with different O2 concentrations (partial pressures), proportional to the temperature in Kelvin degrees (°K) and the logarithm of the ratio between the two pressures PO2’ and PO2” in accordance with Nernst’s well-know ratio:

E = RT / nF (Lg P02’ / P02“)

Where: R = Perfect gas constant (8,31 Joule/degree bulk)

F = Faraday’s constant

T = Absolute temperature in °Kelvin

n = 4

The inner sensing element is a based on a proprietary ADEV technology (micro-pod) and features a solid state reference that completely eliminate the need of a reference air flow, making the instrument very easy and practical to use in field.

- No reference air

- Sensor on the tip

- No gas circulation