Gasanalyse

AtLAS-700 TDLAS Analysator

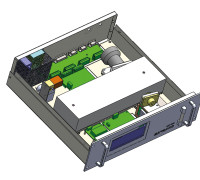

AtLAS-700 is a rack type tunable laser gas analyser for industrial on line applications. The analyser combine the TDLAS technology and multiple reflection long optical path technology that can measure a variety of gas.

AtLAS-700 is a rack type tunable laser gas analyser for industrial on line applications. The analyser combine the TDLAS technology and multiple reflection long optical path technology that can measure a variety of gas.

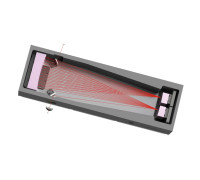

Reflected light can be customized according to the working condition demand, allowing to measure each gas from high percentage down to traces.

Measureable Gas

- Oxygen [O2]

- Water [H2O]

- Hydrogen Fluoride [HF]

- Acetylene [C2H2]

- Carbon Monoxide [CO]

- Hydrogen Sulphide [H2S]

- Ammonia [NH3]

- Ethylene [C2H4]

- Carbon Dioxide [CO2]

- Hydrogen Chloride [HCl]

- Methane [CH4]

- Combined Versions

- Carbon Monoxide + Carbon Dioxide [CO+CO2]

- Ammonia + Water [NH3 + H2O]

- Hydrogen Chloride + Water [HCL + H2O]

- Hydrogen Fluoride + Water [HF + H2O]

Main Features

Strong anti-interference capability

- High accuracy and small drift

- Adopting wavelength modulation spectroscopy allows better anti-interference capability of background gas and higher reliability

Low detection limit, high sensitivity

- Multi-reflection technology achieves optical path up to 25 m, highly improving detection limit.

- The sensitivity can reach ppm level or even ppb level for some components

Compact Structure, Easy Integration

- 19” standard 3U panel chassis, modular design, easy integration with other instrument

- Modular design, laser module field replaceable easy maintenance

Excellent adaptability

- For applications is corrosive environment, all parts of AtLAS-700 exposed to sample gas are made of corrosion-resistant material.

- No inner moving parts

European Compliance

- Low Voltage Directive 2014/35/EU

- EMC Directive 2014/30/EU

|

Performance Specification |

|

|

Measuring Principle |

TDLAS (Tunable Diode Laser Absorption Spectroscopy) |

|

Linearity Error |

≤ ±1% FS |

|

Repeatability |

≤ ±1% FS |

|

Span Drift |

≤ ±1% FS / 6 months |

|

Zero Drift |

≤ ±1% FS / 6 months |

|

Maintenance Cycle |

≤ 2 times / year (related to the working conditions) |

|

Calibration Cycle |

≤ 2 times / year (or automatic calibration) |

|

Enclosure Rating |

IP54 |

|

Response Time |

≤ 30 sec. at T90 (related to the working conditions) |

|

Signals |

|

|

Analog Output |

2 x 4-20 mA isolated (max. load 750 Ω) |

|

Analog Input |

2 x 4-20 mA isolated (for temperature and pressure compensation, if necessary) |

|

Digital Output |

RS485 / RS232 |

|

Relay Output |

3 x (24V, 1A) |

|

Operative Specification |

|

|

Sample Gas Flow |

0.5…2 l/min. |

|

Sample Gas Interface |

Ø6 Bi-lok |

|

Power Supply |

100…240 Vac |

|

Ambient Temperature |

-20°C….+60°C |

|

Ambient Humidity |

≤ 90% non-condensing |

Application

Refinery & Petrochemical

- FCC catalyst regeneration

- SCR NH3 injection

- Desulphurization efficiency

- Explosive process gas,

- Reactant ratio optimization

- HCL, HF emissions

- Flue gas measurement outlet of process heaters, fractionators, thermal crackers, utility boilers & incinerators

- Sulfur recovery

- Slip Ammonia control in deNOx plants

Thermal Power Plant

- SCR NH3 injection

- Desulphurization efficiency

- Coal injection safety control

- HCL, HF emissions

Chemical

- Process O2 safety systems

Metallurgy

- Combustion control for reheating furnace, heat treatment furnace, forging furnace

- Converter gas recycle

- Blast furnace gas

- Coke oven gas

- Flue gas of sintering, pelletizing

- Coal injection safety control

- Electric tar precipitator (ETP) safety control

- CDQ circulating gas

- Gas tank safety control

- Sulfur recovery

Sampling System

The AtLAS-700 needs an external sampling system able to deliver an almost clean sample gas to the analyser at the proper temperature, pressure and flow rate.

ADEV has a wide experience in process and can provide the AtLAS-700 analyser combined with a sample and condition system designed for the specific application requirements. Contact ADEV for details.

Measuring Principle

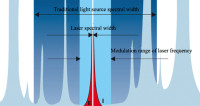

TDLAS (Tunable Diode Laser Absorption Spectroscopy) mainly uses the character that Tunable laser’s narrow band and wavelength change with the current. So, by precisely modulating the current of tunable laser, it can scan a certain absorption peak of detected gas (no absorption of background gas).

And after obtaining the second harmonics absorbed by detected gas, it finally works out the concentration of detected gas by using this second harmonics and line-width.

The TDLAS technology has been developed into a kind of high sensitivity, high resolution, fast response time and high selectivity of gas detection technology, widely used in industrial process monitoring control.

By using a tunable semiconductor laser, AtLAS-700 scans the specific absorption line of the measured gas (no background gas) to get the second harmonic of the gas. Through processing and analyzing the second harmonic and the broadening information of the gas, the concentration of the gas is obtained.