Gasanalyse

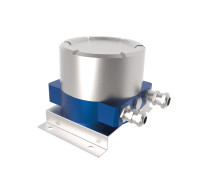

AtLAS-900 in Situ TDLAS Analysator

AtLAS-900 is a laser gas analyser for industrial on line applications, able to measure a great number of gas in situ (cross-stack). The TDLAS technology provide an incredibly fast response time, small drift and measure virtually free from interferences of other gases.

AtLAS-900 is a laser gas analyser for industrial on line applications, able to measure a great number of gas in situ (cross-stack).

The TDLAS technology provide an incredibly fast response time, small drift and measure virtually free from interferences of other gases.

Optimized for heavy industrial applications and available for safe or Hazardous area applications (ATEX Zone 1 / Zone 21), AtLAS-900 features a very robust design and come with all the needed accessories for an easy installation and periodical calibration.

Measureable Gas

- Oxygen [O2]

- Water [H2O]

- Hydrogen Fluoride [HF]

- Acetylene [C2H2]

- Carbon Monoxide [CO]

- Hydrogen Sulphide [H2S]

- Ammonia [NH3]

- Ethylene [C2H4]

- Carbon Dioxide [CO2]

- Hydrogen Chloride [HCl]

- Methane [CH4]

Combined Versions

- Carbon Monoxide + Carbon Dioxide [CO+CO2]

- Ammonia + Water [NH3 + H2O]

- Hydrogen Chloride + Water [HCL + H2O]

- Hydrogen Fluoride + Water [HF + H2O]

Main Features

High Performance

- Adopting wavelength-modulation-spectroscopy allows better signal/noise ratio and anti-interference capability of dust and background gas

- Single line spectrum technology, free from interference of background gas

- Integrated structure design, high stability and reliability

- Almost instantaneous response time

Easy to Use

- Easy optical path adjusting, XY direction non-coupling adjusting

- Modular design makes field maintenance operations very easy

- Simple to clean in case dirty deposits on the optical parts

Low Costs of Ownership

- In situ measurement

- No sampling system required

- Small drift, long maintenance period

Interface

- I/O interface, self-diagnosis and alarm information

- Local OLED display operated by magnetic pen

European Compliance

- Low Voltage Directive 2014/35/EU

- EMC Directive 2014/30/EU

ATEX

ATEX certification for Zone 1 / Zone 21 with protection mode:

II 2 G D Ex db op is IIC T6 Gb Ex

Ex tb op is IIIC T80°C Db

Ta = -20°C to +60°C

ATEX Certificate Number CML 18 ATEX 1400X

SIL 2

SIL 2 [ pending ]

|

Performance Specification |

|

|

Optical Channel Length |

0.3….20 meters [note 1] |

|

Accuracy |

≤ ±1% FS |

|

Linearity Error |

≤ ±1% FS |

|

Repeatability |

≤ ±1% FS |

|

Zero & Span Drift |

≤ ±1% FS / 6 months |

|

Maintenance Cycle |

≤ 2 times / year (clean optical window) |

|

Calibration Cycle |

≤ 2 times / year |

|

Enclosure Rating |

IP66 |

|

Response Time |

≤ 1 sec. at T90 |

|

Signals |

|

|

Analog Output |

2 x 4-20 mA isolated (max. load 750 Ω) |

|

Analog Input |

2 x 4-20 mA isolated [note 2] |

|

Digital Output |

RS485 / RS232 |

|

Relay Output |

3 x (24V, 1A) |

|

Operative Specification |

|

|

Sample Temperature |

0°C…1300°C [note 3] |

|

Pressure |

Max. 3 bar abs. |

|

Dust Content |

≤ 1 g/m3 or ≤ 30 g/m3 |

|

Water Vapor Content |

Whichever, non-condensing |

|

Installation |

In situ (cross-stack) |

|

Process Connection |

By soldering or with flange DN40 PN 1.6 MPa |

|

Route Valve Flange |

DN50 PN 1.6 MPa (standard valve) DN65 PN 1.6 MPa (gate valve for T > 300°C) |

|

Power Supply |

24 Vdc or 100…240 Vac, ≤ 20W |

|

Ambient Temperature |

-20°C….+60°C |

|

Ambient Humidity |

≤ 90% non-condensing |

|

Purge Gas |

Nitrogen or purified instrument air [note 4] Pressure range: 0.3 MPa….0.8 MPa Flow rate: 0…4300 l/h [note 5] Purging gas ports: Ø 8 mm |

|

Wiring Connections |

ATEX version: 1 x armored cable gland for cable 6.5÷10.5 mm. Safe area version: 2 x cable glands for cable 5÷8 mm 3 x threaded hole M20 x 1.5 (with plug) 1 x threaded hole M25 x 1.5 (with plug) |

[Note 1]

Minimum optical path depends on gas to be measured and range. Contact ADEV

[Note 2]

For eventual live compensations of temperature, pressure and O2 impurities inside purging Nitrogen, if used.

[Note 3]

For process temperature > 500°C water cooling system is required. Contact ADEV.

[Note 4]

Instrument air cannot be used as purging gas in case the gas to be measured is O2 and process gas temperature is < 400°C

[Note 5]

The precise flow rate of purging gas cannot be predetermined. It depends on several factors just like pressure and flow rate of sample gas, dust amount and type.

Minimum suggested:

- for pants working in positive pressure: 500 l/h

- for pants working in positive pressure: 350 l/h

Applications

- Combustion control & Emissions

- Slip Ammonia control in deNOx plants

- Process and Safety Monitoring

- Inerting Control

- Solvents & Sulfur Recovery

- Chemical and Petrochemical Industry

- Steel Industry

- Blast furnace gas and Coke oven gas

- Coal injection safety control

- Power Plants

- SCR NH3 injection

- FCC catalyst regeneration

- Electric tar precipitator (ETP) safety control

- Flue gas measurement outlet of process heaters, fractionators, thermal crackers, utility boilers & incinerators

Measuring Principle

TDLAS (Tunable Diode Laser Absorption Spectroscopy) mainly uses the character that Tunable laser’s narrow band and wavelength change with the current. So, by precisely modulating the current of tunable laser, it can scan a certain absorption peak of detected gas (no absorption of background gas).

And after obtaining the second harmonics absorbed by detected gas, it finally works out the concentration of detected gas by using this second harmonics and line-width.

The TDLAS technology has been developed into a kind of high sensitivity, high resolution, fast response time and high selectivity of gas detection technology, widely used in industrial process monitoring control.

By using a tunable semiconductor laser, AtLAS-900 scans the specific absorption line of the measured gas (no background gas) to get the second harmonic of the gas. Through processing and analyzing the second harmonic and the broadening information of the gas, the concentration of the gas is obtained.